Chapter 5

I 1788 - State Of The Art In Textile Technology

II Australian Textiles - The Early Days

III Australian Textiles - The 20th Century

i Technology and Development

ii Australian Wool Textile Research

IV Australian Textiles - To Date

V Acknowledgements

References

Index

Search

Help

Contact us

Australian Wool Textile Research (continued)

The chlorine-Hercosett process was developed industrially in collaboration with the Australian Wool Corporation (A.W.C.) and the company Villawool Ltd. in Sydney, and then extended internationally by the International Wool Secretariat.Of all the processes in the conversion of raw wool to fabric, spinning in the 1950s-1960s was the slowest and most time-consuming. Together with associated processes (winding, steaming, twisting), it accounts for approximately half of the conversion cost from raw fibre to yarn. Even today, despite the very significant advances made over the past three decades, spinning constitutes a bottleneck in yarn production, and labour and power costs are high. For these reasons, research to improve the economics of spinning has always had high priority. At the time, research was underway overseas to develop the open-end system of spinning for cotton. This was not satisfactory for wool, and effort was required to ensure faster rates of spinning were available for the fibre.

For wool worsted yarns intended for weaving, as well as the operation of spinning, a further twisting operation is required whereby two single yarns are twisted about each other (twofolding). In both spinning and twisting, there are limitations on the speed at which the twist can be applied. For wool, this results in a typical linear production speed of 15-20 metres per minute.

During the early 1960s, with these limitations in mind, CSIRO Geelong began looking for alternative techniques of yarn formation. This quickly led to the idea[25] of making two-ply yarns by applying alternating 'Z' and 'S' twist to a pair of drafted rovings and then allowing them to combine and untwist around each other. This 'self-twist' system was eventually developed to a commercial stage in collaboration with Repco Ltd., Melbourne. The machine (Fig. 19) required significant engineering innovation. For example, the use of butadiene covered rollers that, as well as rotating to feed the strands forward, also oscillated from side to side, each roller moving in opposite directions, to impart alternating twist (Fig. 20) to each strand. These rollers utilized a unique system of air bearings.[26]

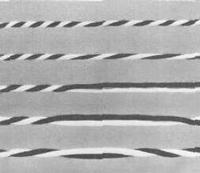

Between adjacent S and Z two-ply twists is a zone containing no twist. This is shown in the fourth photograph, which is a weak point in the structure. Therefore, a yarn in this form is unsuitable for weaving. The necessary strength is given to the yarn by a subsequent twisting operation. The final photograph shows in five discrete steps the effect of adding unidirectional twist to a self-twist structure. When additional twist is applied, the twist in the right-hand portion of the yarn (a) increases as the yarn to the left of the no-twist zone starts to untwist (b). Further twisting removes all twists from the left half of the yarn (c), without the loss of roving twist. Addition of more twist results in the condition shown in (d), where all the twist is unidirectional, and finally in that shown in (e), where twist distribution approaches uniformity. The yarn in this form has the necessary characteristics for fabric weaving.

In the early stages of the development of self-twist, many methods of making alternating-twist structures were considered. The conflicting requirements of high-twist insertion accompanied by low strand tension to avoid strand breakage limited the choice of methods. A reciprocating roller system fulfilled these requirements, with the added prospect of very high production rates.

Using the reciprocating roller system, two separated parallel rovings are first conventionally drafted and then enter the nip of a pair of rollers, which not only rotate, but simultaneously reciprocate through equal distances in opposite directions.

The frictional contact between the rotating rollers and the strands carries the latter forward, and the traverse motion of the rollers rolls the strands, causing them to twist. By this means alternate zones of S and Z twist are imparted progressively to the separate strands as they pass through the rollers. Finally, the two twisted strands are combined and twist about one another to form a stable two-ply structure.

Under licence to CSIRO, Repco established a company in Australia to manufacture the equipment and appointed the British company, Platt Ltd., to market the machine overseas. Eventually, Repco also licensed Platt to manufacture the machine and, because of higher costs locally, in due course, ceased manufacture in Australia.

The machine offered significant advantages over conventional spinning: it was smaller, quieter, used less energy and, above all, was 10-15 times faster, operating at speeds up to 300 m/min. It had the limitation, however, that the yarn produced was quite different in structure from the conventional yarn produced by ring-spinning. This tended to restrict its market acceptance; self-twist wool yarns were generally un-uitable for knitting, and in weaving, the nature of the fabric produced in some constructions was different from the same construction produced from conventional yarns. Nevertheless, over 3000 machines (equivalent to at least 300,000 conventional spindles) have been sold, the first to Macquarie Worsteds Pty. Ltd., Albury, and most of these are still in use today (1986). Both Macquarie Worsteds and the company, Aspin Pty. Ltd., Melbourne, two of the three major worsted yarn spinners in Australia, continue to produce significant quantities of self-twist yarns.

Organisations in Australian Science at Work - Aspin Pty Ltd; Australian Wool Corporation; CSIRO Division of Textile Industry; Macquarie Worsteds Group; Repco Corporation Ltd; Villawool Ltd, Sydney

|

Australian Academy of Technological Sciences and Engineering |  |

© 1988 Print Edition pages 282 - 284, Online Edition 2000

Published by Australian Science and Technology Heritage Centre, using the Web Academic Resource Publisher

http://www.austehc.unimelb.edu.au/tia/290.html